Polyvinyl alcohols (PVOH,PVA) for thermal paper coloring layers

Thermal paper contains a colorant which undergoes a chemical reaction above a certain temperature. In this article we explain the basics about thermal paper and the mechanism of thermal printing, and introduce GOHSENX™ L, a synthetic resin that can be used as a thermal dye dispersant to improve the printing performance of thermal paper.

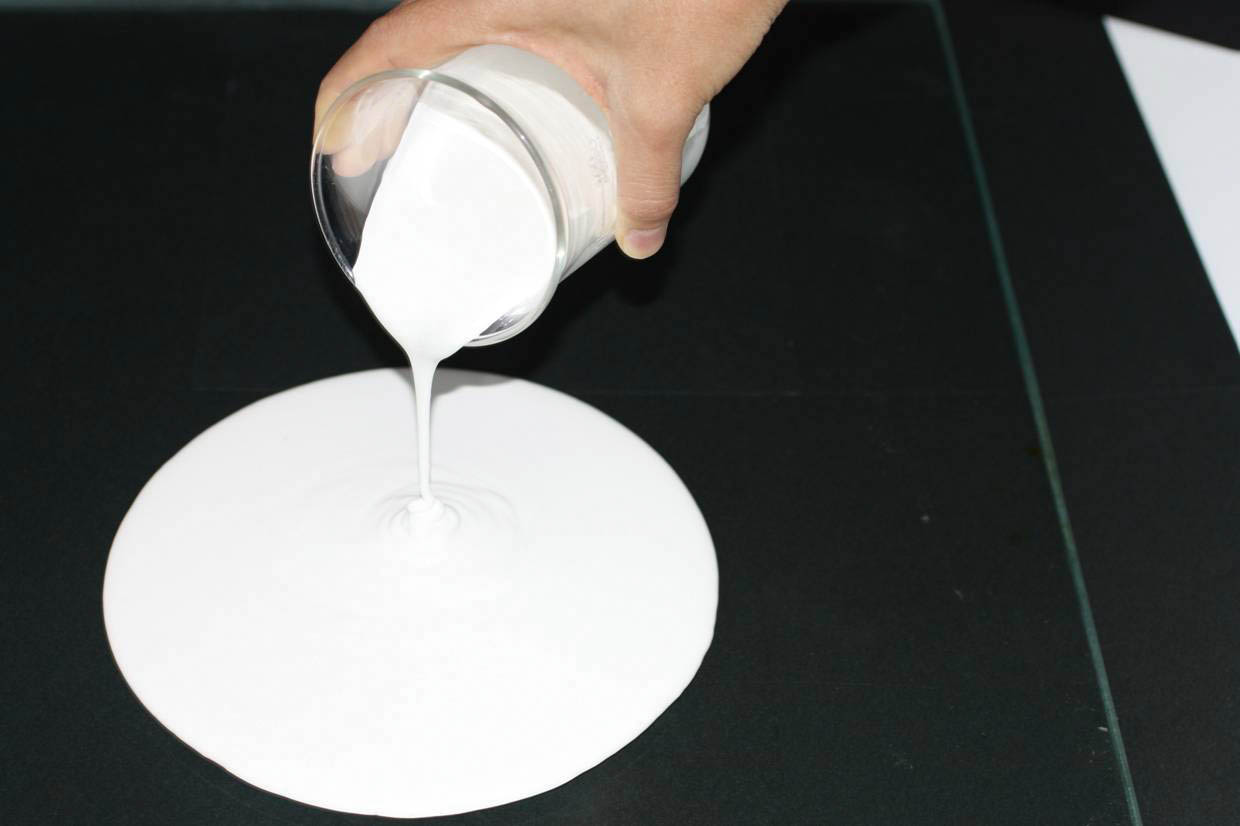

PVOH use for receipts (thermal paper)

The receipts and barcodes that are part of our everyday shopping use functionalized paper known as thermal paper.

Thermal paper contains a colorant which undergoes a chemical reaction above a certain temperature. This colorant turns black when the location that needs to be printed is heated by a dedicated thermal printer.

The use of thermal paper offers many advantages. Printing is extremely rapid, there is no need for ink or toner, printers for thermal paper can be miniaturized and made lightweight, and the running costs are low. As a result, thermal paper is used not just for receipts but also a wide range of other applications such as logistics barcode labels, air tickets, lottery tickets, and labels for medical use.

And this familiar material contains polyvinyl alcohols (PVOH,PVA)!

What is thermal paper?

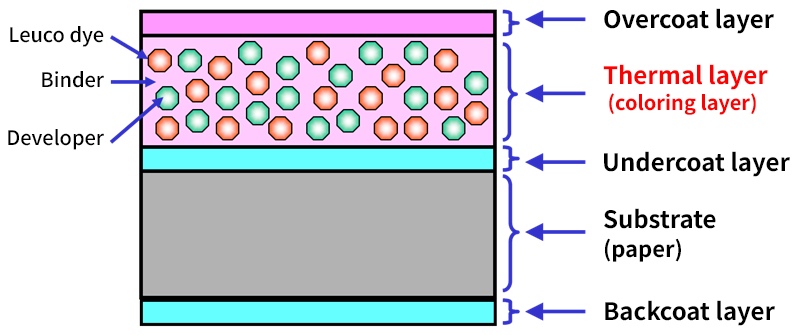

Thermal paper composition

The role of each layer is described below.

Overcoat layer: Increases durability by protecting against light, water, alcohols, etc.

Coloring layer: Creates a black color via the heat-initiated reaction of a leuco dye and color developer.

Undercoat layer: Smooths out the unevenness of the paper and acts as an insulator to increase the heat responsiveness

Substrate: Paper is used as a support

Backcoat layer: Prevents paper curling and stops chemicals penetrating the paper from the reverse side.

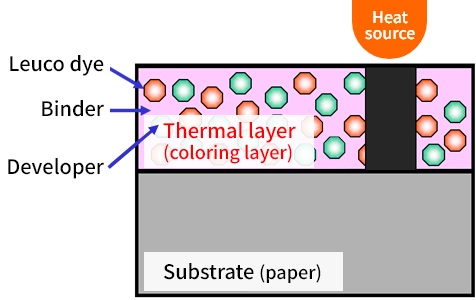

Color generation mechanism

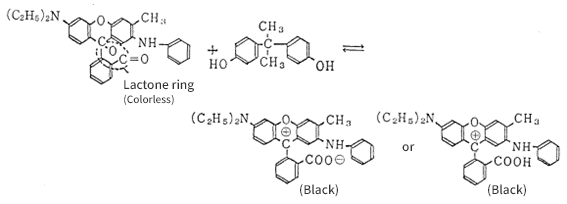

When the printer head in the thermal printer applies heat to the surface of the thermal paper, the finely dispersed leuco dye and developer in the coloring layer melt and come together, a chemical reaction occurs, and the printed characters and shapes assume a black color.

The colorants are as follows.

Leuco dye: Thermal dye, mainly ODB2.

Developer: Acidic compound. Phenolics (mainly BPA).

Leuco dye coloring mechanism

The twin roles of PVOH in the coloring layer

The PVOH plays two roles. As well as being used as a dispersant for the leuco dye and developer in the coloring layer, it acts as a binder for the dispersed leuco dye and developer.

As dispersant

For the thermal paper to rapidly create color with good print resolution, the leuco dye and developer in the coloring layer must be in a finely dispersed state.

Particles which are smaller than a certain size will tend to reagglomerate and destabilize the particle dispersion. When used as a dispersant, PVOH is adsorbed at the surface of the dispersed leuco dye and developer particles and functions as a protective colloid. This prevents the dispersed particles from reagglomerating with each other and increases the stability of the liquid dispersion.

As binder

The PVOH fixes the leuco dye and developer dispersed in the coloring layer, and creates good adhesion between the substrate and coloring layer.

GOSENEX™ L for improved dispersiveness

In Europe, usage of the bisphenol-type developer BPA in thermal paper was prohibited in 2020 due to its risk to human health and the environment.

The switch to safer developers (other phenolics or non-phenolic developers) is progressing but some of the new materials are proving to be more difficult to disperse than BPA. In these cases, the dispersiveness of existing PVOH dispersants is insufficient.

GOHSENX™ L is a specially modified PVOH that contains strongly anionic groups. When adsorbed by the dispersed particles, these groups provide strong electrical repulsion to deter particle reagglomeration and increase the dispersiveness.

We recommend GOHSENX™ L for customers looking for higher dispersiveness than that provided by conventional PVOH, or those concerned about the dispersiveness of specific developers.

-scaled.jpg)