Gas barrier package materials (extrusion casting)

Application Examples of Nichigo G-Polymer™ | Gas Barrier Films

Nichigo G-Polymer™ demonstrates the highest gas barrier performance among thermoplastic resins at low humidity.

In order to prevent the loss of gas barrier performance at high humidity, a multilayer structure is effective.

For screw design and temperature slopes, see “Basic properties,” “Extrusion performance,” and “Extrusion casting temperature range and temperature slope.”

Oxygen permeability of Nichigo G-Polymer™ (humidity dependence)

The figure below indicates that Nichigo G-Polymer™ has higher barrier performance than EVOH at low humidity.

Samples: PP/tie/Nichigo G-Polymer™ BVE8049P (or EVOH)/tie/PP multilayer film

Measurement conditions: 23°C

Example of film layer structure

Film layer structures of coextruded multilayer films, extrusion coated films, and paper coatings.

The structure of coextruded multilayer film is as follows.

[Coextruded multilayer film]

PE/tie/Nichigo G-Polymer™/tie/PE

PP/tie/Nichigo G-Polymer™/tie/PP

Ny/tie/Nichigo G-Polymer™/tie/sealant

The structure of extrusion coated film is as follows.

[Extrusion coated film]

O-PET//Nichigo G-Polymer™/tie/PE

The structures of paper coatings are as follows.

[Paper coating]

Paper//Nichigo G-Polymer™/tie/PE

(When collected, the Nichigo G-Polymer™ layer is melted, and the paper and PE layers are easily detached.)

Paper//PE/tie/Nichigo G-Polymer™/tie/PE

[Reference]

See “Extrusion performance” for: Treatment temperature conditions, Inflation treatment condition examples, and Extrusion casting treatment condition examples.

Application Examples of Nichigo G-Polymer™ | Films [water soluble]

Nichigo G-Polymer™ single layer films have excellent low temperature water solubility.

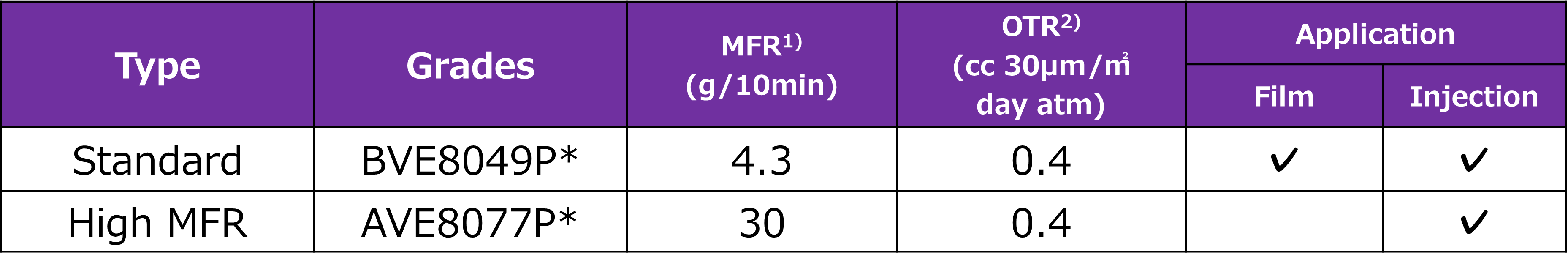

Recommended grades of Nichigo G-Polymer™ for water soluble film applications

Recommended grades of Nichigo G-Polymer™ for water soluble films include basic grade and high fluidity grade. The respective grades, MFR, and applicability (T die cast and inflation) are as listed below.

1): 2,160 gf, 210°C

* Recommended grade for food package applications

The numbers above are sample values, and are not guaranteed.

Water dissolution rate of water soluble film using Nichigo G-Polymer™

Dissolution rate substantially varies depending on the film (plate) thickness, water dissolution temperature, and stirring method.

The figure below indicates that dissolution time varies at the same temperature depending on film (plate) thickness.

Sample: Nichigo G-Polymer™ BVE8049P single layer film or plate (25 × 50 mm)

Sample: Nichigo G-Polymer™ BVE8049P single layer film or plate (25 × 50 mm)

[Measurement method]

Films and plates were immersed in stirred water controlled at each temperature, and the time to complete dissolution was measured.

Stirring: Three-One Motor, 300 rpm

[Reference]

See “Extrusion performance” for: Treatment temperature conditions, Inflation treatment condition examples, and Extrusion casting treatment condition examples.

Applications of Nichigo G-Polymer™ are also described in the following articles.

Bottle application of Nichigo G-Polymer™: https://www.g-polymer.com/eng/petbotoru/

Solution coating film application of Nichigo G-Polymer™: https://www.g-polymer.com/eng/coatfilm/

Injection molding application of Nichigo G-Polymer™: https://www.g-polymer.com/eng/syasyutu/

Biodegradable barrier package material application of Nichigo G-Polymer™: https://www.g-polymer.com/eng/barrier_film/index.html

Extrusion Performance of Nichigo G-Polymer™

Nichigo G-Polymer™ is a resin capable of extrusion casting.

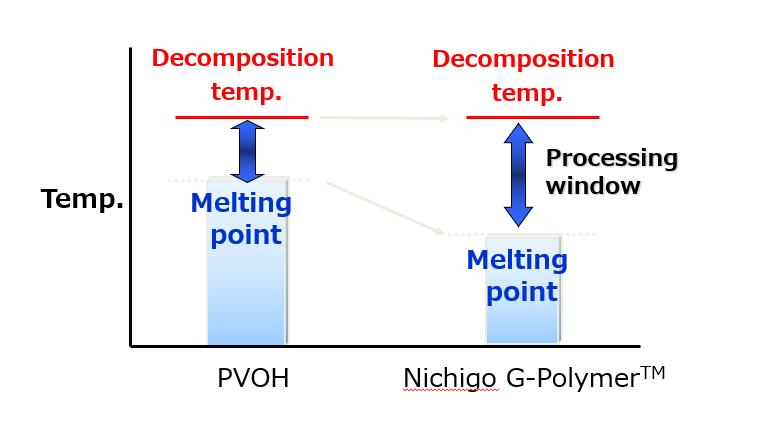

Compared to PVOH, Nichigo G-Polymer™ has a lower melting point and a wider casting temperature range, giving it outstanding extrusion performance.