Polyvinyl alcohols (PVOH,PVA): Features and specifications

Polyvinyl alcohols, also known as PVOH, PVA, or Poval, are synthetic resins. In this article we explain the basics about PVOH, their history and features, and provide some examples of actual usages and product recommendations.

What are PVOH?

We will start by explaining what PVOH are, and how they have come to be made. First let’s deal with the basics.

Overview

Polyvinyl alcohols, also known as PVOH, PVA, or Poval, are synthetic resins.

They are produced by the saponification of polyvinyl acetate, which is prepared by the polymerization of vinyl acetate.

The molecular weight (degree of polymerization) of a polymer shows how big it is. PVOH contain hydroxy (OH) groups and acetyl groups, and the ratio of OH groups to the total of the two groups is called the degree of saponification. Various PVOH products can be obtained by varying the molecular weight (degree of polymerization) and degree of saponification.

History

PVOH were discovered in 1924 by the German chemists W.O. Herrmann and W. Haehnel.

In Japan, the Nippon Synthetic Chemical Industry Co. Ltd. started manufacturing PVOH in 1950, since which they have found widespread use in all kinds of applications. After the takeover of Nippon Synthetic Chemical Industry Co. Ltd., these PVOH are now produced and sold by Mitsubishi Chemical.

Special features

PVOH have several special features, four of which are introduced here.

(1) Water solubility

PVOH are water soluble resins, with the solubility increasing with temperature. In contrast, they are insoluble in most organic solvents.

Please click here for details.

(2) Adhesion

PVOH exhibit excellent adhesion to hydrophilic materials such as wood, paper, and cloth. They provide high adhesive strength and are safe and easy to use.

Please click here for details.

(3) Surface activity

Partly saponified PVOH are highly surface active materials and can be used as protective colloids.

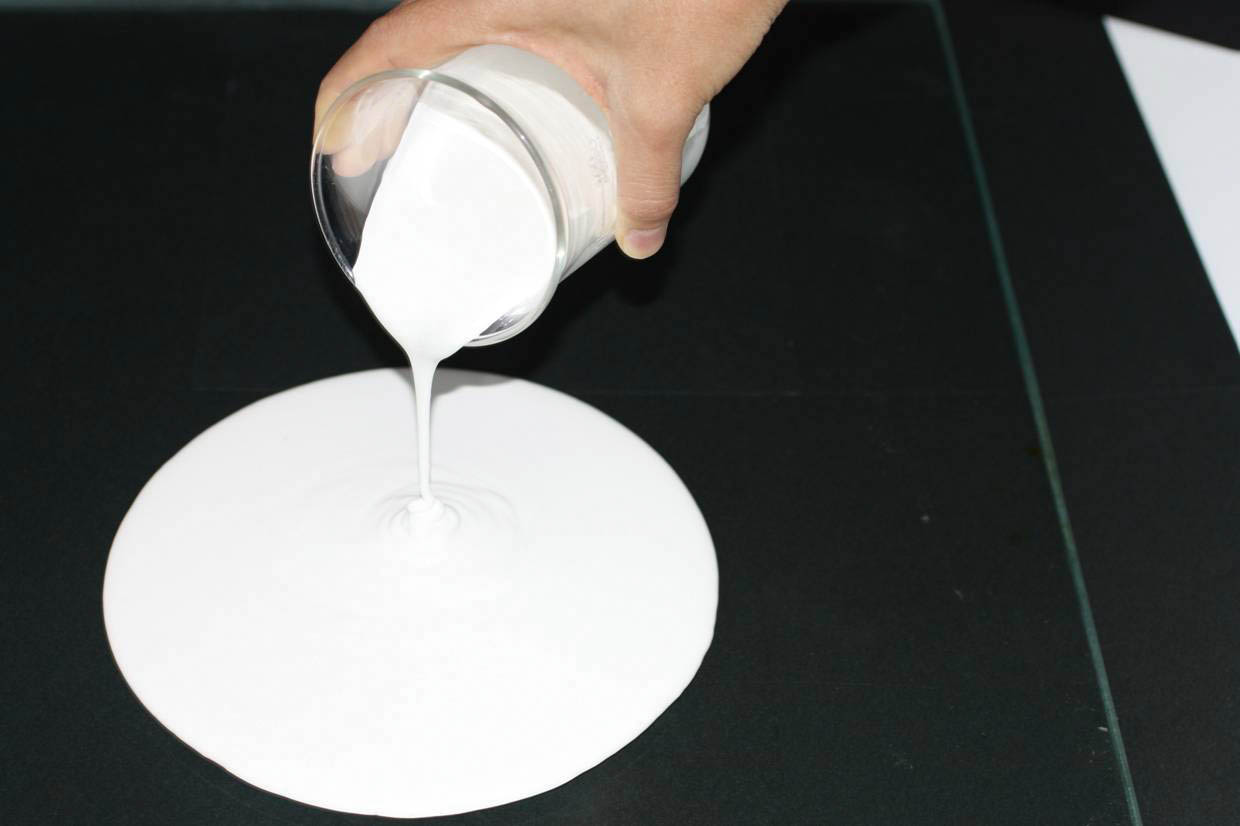

(4) Film forming properties

PVOH have excellent film forming properties and form tough and flexible films.

Examples of PVOH in use

Due to the above-mentioned features, PVOH have a diverse range of uses.

Some examples of how they are actually used are shown below.

Adhesives and binders

PVOH are used in products such as adhesives for plywood, remoistening glues, and backing glues for postage stamps.

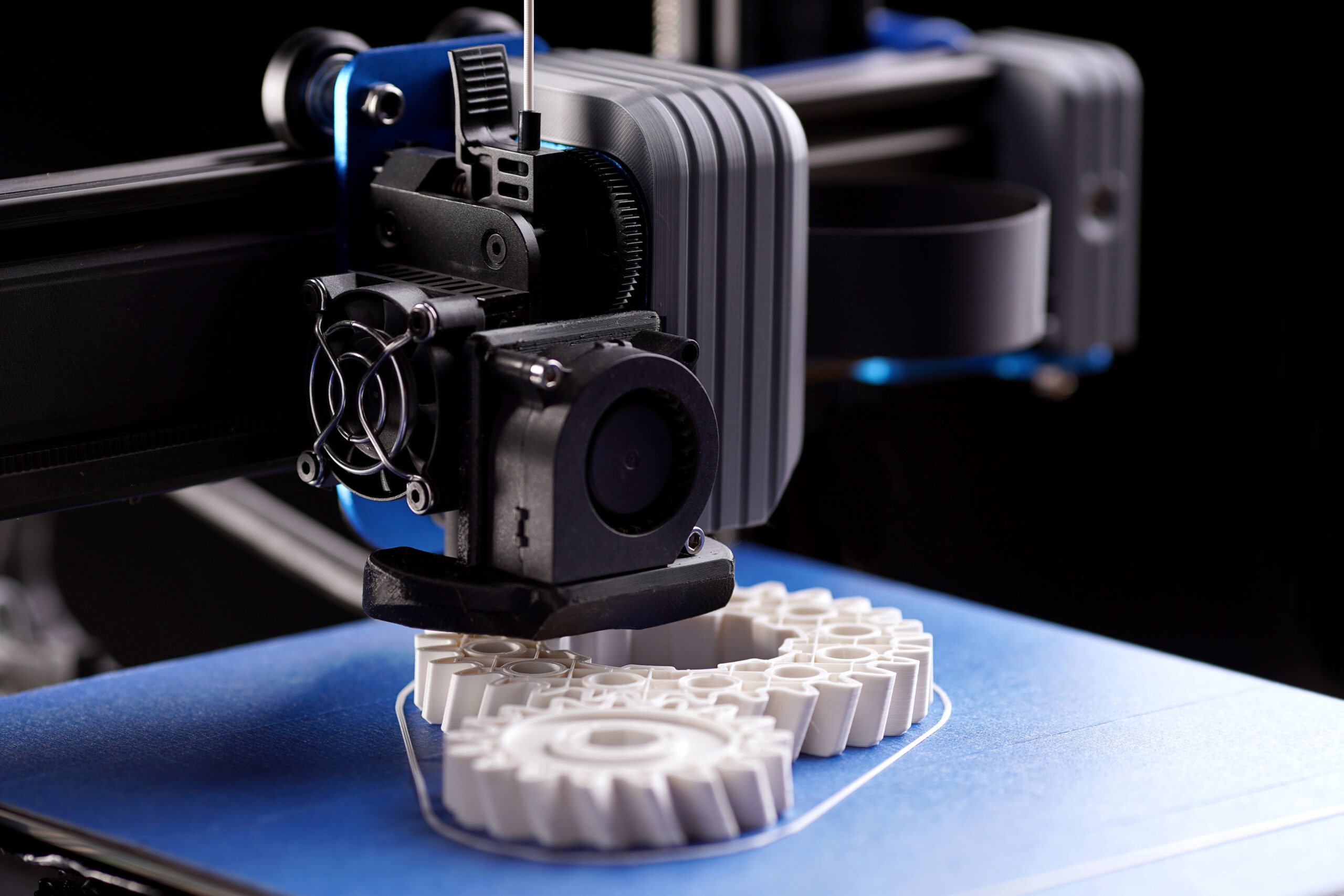

They are also used as binders for inorganic materials such as ceramics. Such binders need to exhibit the twin characteristics of no deformation under zero load (shape retention) and formability (fluidity) when a large external force is applied.

Please click here for details.

Paper processing agents

PVOH are used in surface coatings for Western-style paper, paperboard, specialty paper, etc.

Coating these types of paper with PVOH can result in improved printability and oil resistance, and strengthens the substrate.

Please click here for details.

Emulsifiers

PVOH are used as emulsifiers for polyvinyl acetate emulsions which are the main component of woodworking adhesives. An emulsion is either a dispersion of oil in water, or a dispersion of water in oil.

Please click here for details.

Suspension agents

PVOH are used as suspension agents during the polymerization of polyvinyl chloride (PVC) resins. PVC with a particle size 50 to 200 μm is produced by suspending vinyl chloride monomer in water using stirring and a dispersant, and polymerizing it over several hours.

Please click here for details.

Films

By coating a base material with PVOH aqueous solution, high gas barrier performance can be added to a barrier film.

Please click here for details.

Finally in this article, we will introduce the PVOH products produced and sold by Mitsubishi Chemical.

Mitsubishi Chemical PVOH product range

Mitsubishi Chemical sells PVOH under the general brand name of GOHSENOL™. We have also developed a range of specially modified polyvinyl alcohols named GOHSENX™ and Nichigo G-Polymer™.

The introduction of modifying groups into GOHSENX™ and Nichigo G-Polymer™ gives these products additional functionality that is not present in regular PVOH. Depending on the grade, GOHSENX™ provides either superior cross-linking properties or better dispersiveness. Nichigo G-Polymer™ is a biodegradable, melt-formable vinyl alcohol resin with excellent gas barrier properties and water solubility. It has been certified as biodegradable by many countries, as well as being confirmed as biodegradable in seawater conditions. Nichigo G-Polymer™ is also compliant with food hygiene regulations in many countries.

Please see below for details about PVOH from Mitsubishi Chemical.

-scaled.jpg)