It’s also used for this? Polyvinyl alcohols (PVOH,PVA) for wood adhesives

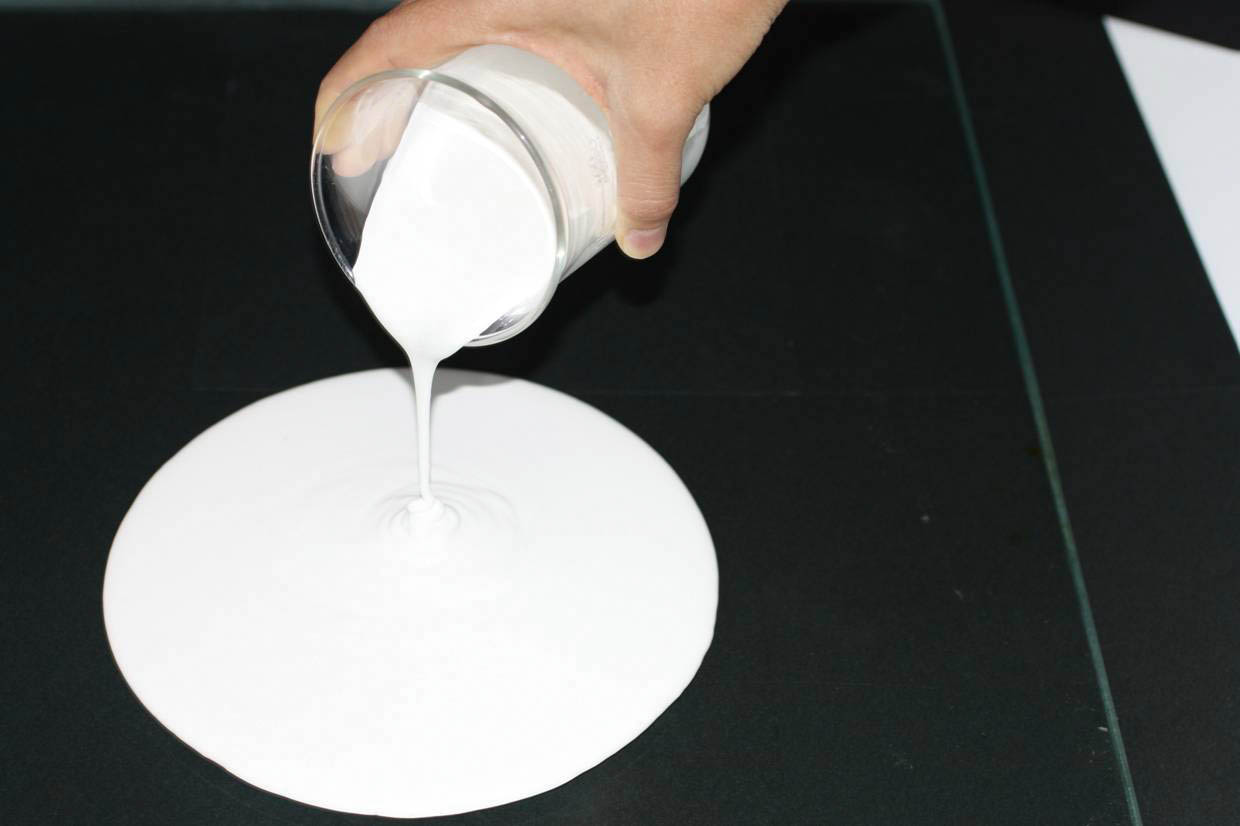

Wood adhesives are familiar products, indispensable for woodwork and DIY. Simply coat wood or paper with the milky-looking adhesive, fix in place and leave until it has dried and become transparent. Polyvinyl alcohols (PVOH,PVA) are a key raw material for these products. In this article, we explain the role of PVOH in wood adhesives.

What are wood adhesives?

Adhesive types and adhesion mechanism

Wood bonding adhesives are typically of the following types.

Solvent evaporation type

After coating, the adhesive is left to dry and the solvent allowed to evaporate. These adhesives harden by losing their liquidity. Capable of drying even at room temperature, they are easy to use. Emulsions are versions that use water as the solvent and are safer due to their lower toxicity. Typified by polyvinyl acetate emulsions, these are used as adhesives for woodwork and construction materials.

Heat curing type

After coating, the adhesive is heated and a chemical reaction occurs between the adhesive components. These adhesives harden by crosslinking between resins. Although heating is normally required to reach the temperatures necessary for hardening, the cured adhesives have superior water resistance and durability. Typified by phenolic, urea, or melamine resins, these are used for plywood and as structural adhesives.

Polyvinyl acetate emulsions and their production

Polyvinyl acetate emulsion adhesives are widely used for woodworking. They are safe and easy to use, and relatively simple to manufacture. The industrial manufacture of polyvinyl acetate emulsions is normally carried out by emulsion polymerization. After dispersing vinyl acetate monomer in water containing an emulsifier (PVOH) and polymerization initiator, the mixture is heated to initiate the polymerization reaction. The product is an emulsion, a milky liquid in which tiny particles of polyvinyl acetate resin are dispersed.

The role of PVOH in polyvinyl acetate emulsions

PVOH is widely used as both an emulsifier and protective colloid during the emulsion polymerization of vinyl acetate. When used as an emulsifier, it provides the following benefits.

Polymerization reaction stabilization

The high surface activity of PVOH keeps the vinyl acetate monomer finely dispersed in the water, ensuring a stable polymerization reaction.

Emulsion stability (protective colloid function)

PVOH plays an important role in polyvinyl acetate emulsions as a protective colloid. During the polymerization reaction, it grafts to and forms chemical bonds with the vinyl acetate. PVOH gathers around the polyvinyl acetate oil droplets and forms a thick and tough layer of hydrated polyvinyl alcohol (protective colloid layer). By protecting the oil droplets in such a way, this layer prevents them from agglomerating even if the emulsion temperature drops or strong mechanical shear is applied, and therefore ensures a stable emulsion.

Coated film mechanical properties

PVOH strengthens the dried emulsio film by increasing cohesive forces due to hydrogen bonding.

Adhesion to cellulose

The presence of highly hydrophilic PVOH at the surface of the polyvinyl acetate oil droplets promotes adhesion to hydrophilic substrates such as paper and cellulose fibers.

Improvement of water-resistant adhesion of polyvinyl acetate emulsions

Although polyvinyl acetate emulsions have gained popularity as wood adhesives, problems with water resistance mean they can rarely be used for applications that need good water resistance and durability, such as structural adhesives. In contrast, the phenolic and other heat-cured resins that are normally used for such applications contain formaldehyde and other substances that are thought to cause sick-house syndrome. This has led to growing demands for polyvinyl acetate emulsions with improved water resistance.

-scaled.jpg)