Biodegradable barrier package materials

Nichigo G-Polymer™ as a Biodegradable Barrier Packaging Material

Fully biodegradable barrier package materials can be designed by using Nichigo G-Polymer™ as an intermediate barrier layer and combining it with biodegradable resins such as polylactic acid (PLA) and polybutylene succinate (PBS) and a biodegradable bonding resin developed by Mitsubishi Chemical.

Nichigo G-Polymer™ is used as an intermediate layer (barrier layer) for biodegradable barrier packaging materials, as shown in the photo below.

Recommended grades when using Nichigo G-Polymer™ as a material for biodegradable gas barrier packaging

The table below lists recommended grades and corresponding products, MFR, and OTR for using Nichigo G-Polymer™ as a material for biodegradable gas barrier packaging. The corresponding product and MFR of biodegradable bonding resins are also listed. All grades are recommended for food package applications.

| Type | Grades | MFR 1) | OTR 2) |

| Standard | BVE8049P | 4.3 | 0.4 |

| High MFR | AVE8077P | 30 | 0.4 |

| Flexibility | OKS-8074P | 3.5 | 0.5 |

| Biodegradable tie resin | G-Connect™ BTR8002P | ≦5 | – |

1): 2,160 gf, 210°C

2): 23°C, 65%RH

OKS: product under development

The numbers above are sample values, and are not guaranteed.

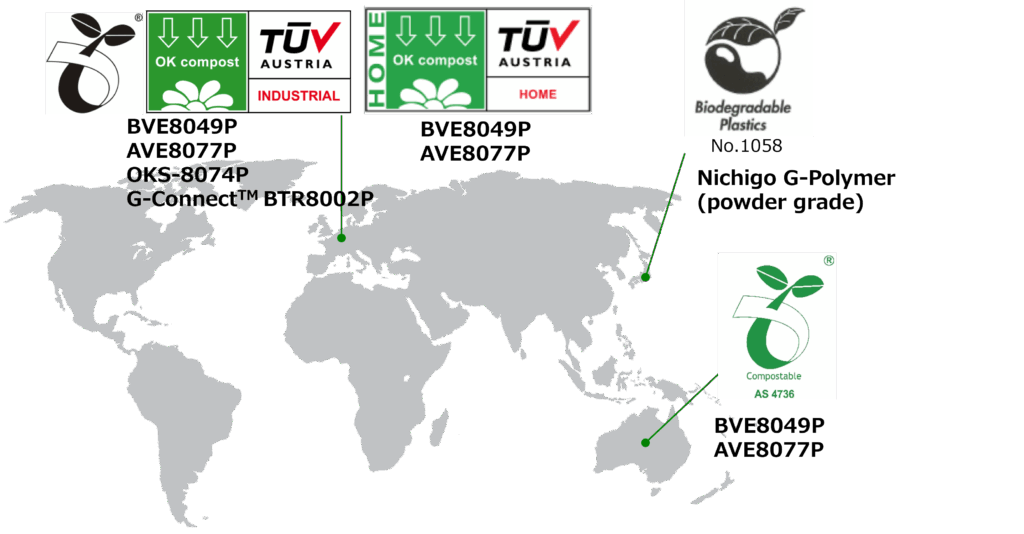

Biodegradability of Nichigo G-Polymer™

Nichigo G-Polymer™ BVE8049P, AVE8077P, OKS-8074P, and biodegradable bonding resin G-Connect™ BTR8002P have acquired the EU biodegradability certification of “OK compost”.

Oxygen permeability of multilayer containers

The table below lists the oxygen permeability of Nichigo G-Polymer™ when used as a material for multilayer containers.

| Layer (µm) | OTR(cc/tray day air)23℃, inner 85%RH, outer 50%RH |

| PLA/G-Connect™ BTR8002P/ Nichigo G-Polymer™ BVE8049P/ G-Connect™ BTR8002P/PLA93/9/9/9/93 | 0.001 |