lost-core and outer-core

Nichigo G-Polymer™ can be used as a lost-core and outer-core material.

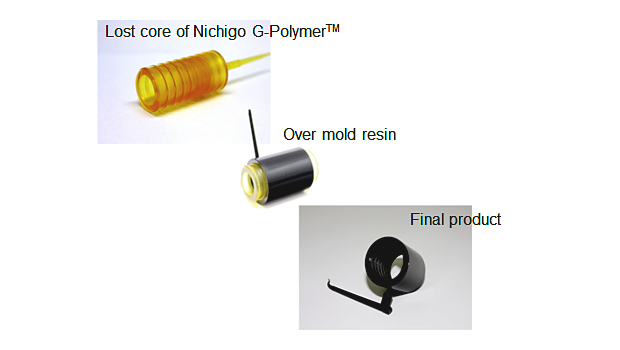

The "lost core" method, which melts and removes the core, has been developed as a molding method to obtain cylindrical resin integrally molded products that are curved or have complex hollow parts.

It is possible to produce a lost-core using Nichigo G-Polymer™ through ordinary injection molding. The lost-core can be easily removed using warm water (cold water).

It is also possible to adjust the dissolution rate, resin strength, fluidity, flexibility and thermal deformation by optimizing resin properties.

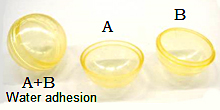

Hollow Lost-Core

Since it can be bonded with water, it is possible to create hollow lost-cores. (If the strength is insufficient, you can increase it by installing a crosspiece inside or filling it with sand, beads, etc.)

[Advantages of a hollow lost-core]

– Reduced use amount of lost-core resin

– Reduced time for wash-out of the lost-core

– Reduced waste water

Images of Use

Basic information

It is possible to integrally form molded products with complex internal shapes that previously required assembling multiple parts.

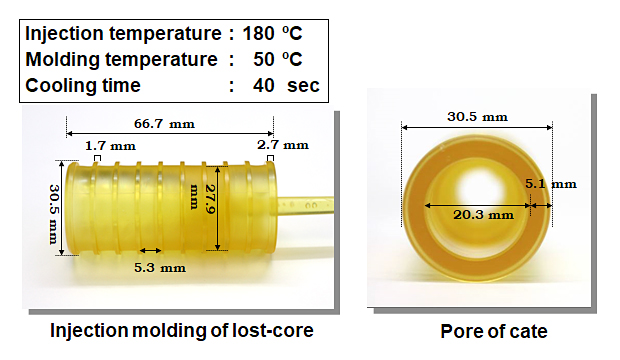

* Data on Nichigo G-Polymer™ BVE8049P

Practical Examples

Lost-core produced through injection molding using Nichigo G-Polymer™ BVE8049P

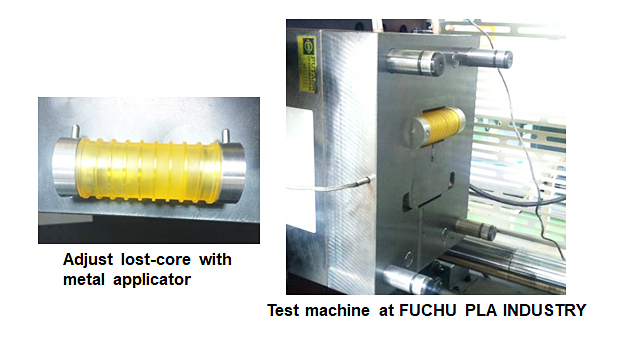

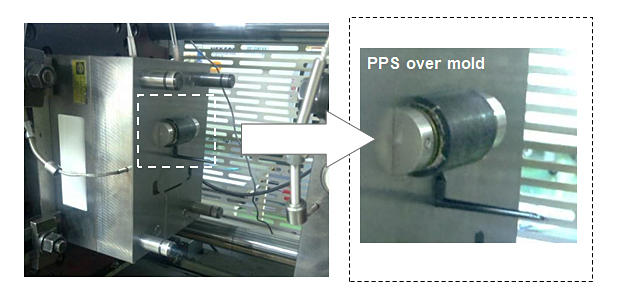

Fixating a lost-core to an injection machine

Over-molding resin (PPS) by injection

State after over-molding

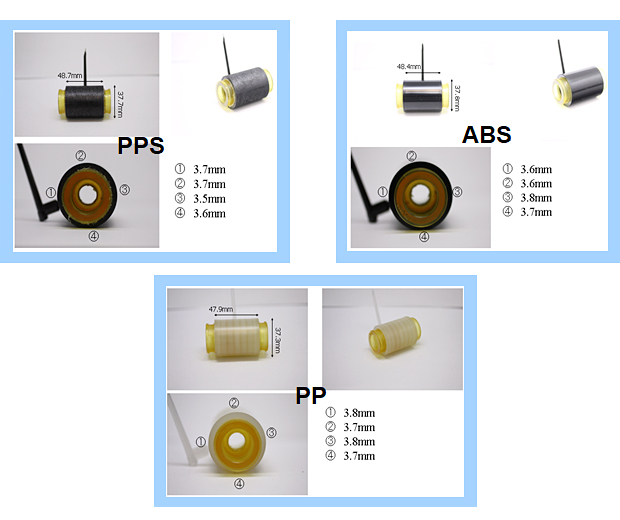

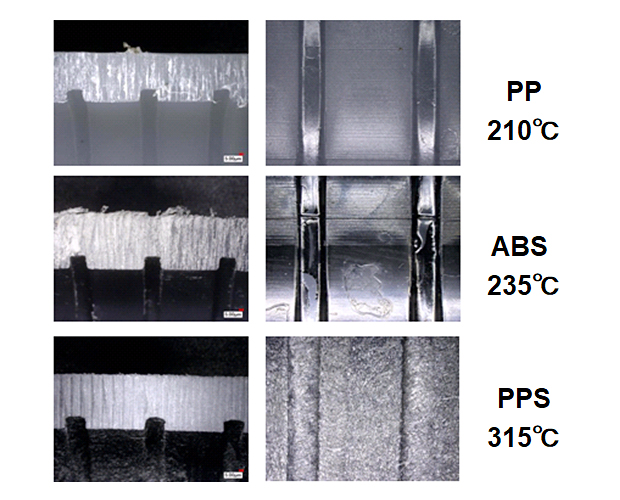

Evaluation of molded products

Evaluation of injection molding using a Nichigo G-Polymer™ hollow lost-core

Wash-out of lost-core

To reduce the wash-out time of the lost-core,

– Increase the temperature of the washing water.

– Contact with running water.

– Manage the aqueous solution concentration to below 20wt%.