Anionic PVOH T Series

Anionic PVOH T Series: Information

GOHSENX™ T Series

The product is a specially modified anionic PVOH with a carboxyl group in the molecular structure.

As a coating agent (especially for paper), adhesive, and binder, the product has been widely used both in global and domestic markets based on the excellent solubility, bonding strength, and reactivity due to its carboxyl group.

Structural formula

Properties

・Aqueous solutions exhibit polyelectrolyte behavior.

・Excellent water solubility

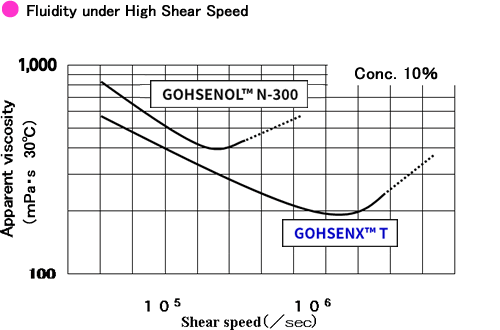

・The aqueous solution has excellent viscosity stability, is less prone to flow abnormalities under high shear rates, and has good high-speed coating properties.

・Excellent solubility in aqueous alkali solutions

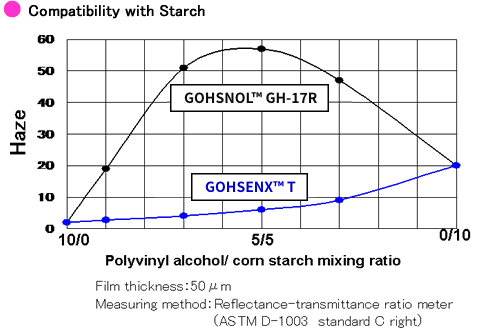

・ Features favorable compatibility with water-soluble polymers, such as starch

・Forms a chelate with metal ions (especially aluminum ions), crosslinks them, and insolubilizes them.

・Greatly improves the surface and Z-axis strength of paper when coated

・Effectively improves the barrier performance of paper

Quality and specifications of GOHSENX™ T

| Grades | Saponification value(mol%) | Viscosity *1(mPa・s) |

| T-330H | ≧99.0 | 27.0~32.0 |

| T-330S *2 | 95.0~98.0 | 27.0~33.0 |

| T-350 | 93.0~95.0 | 27.0~33.0 |

*1: 4% aqueous solution at 20°C

*2: Fine powder type

Crosslinking with polyamide epichlorohydrin resin

| Product | Amount of Cross-linker(%) | Film Drying Conditions | Elution Rate(%) |

| GOHSENX™ T Series | 0 | 23℃× blow-drying 70℃ × 2min 70℃ × 10min | 100 100 100 |

| 5 | 23℃ × blow-drying 70℃ × 2min 70℃ × 10min | 100 100 64 | |

| 10 | 23℃ × blow-drying 70℃ × 2min 70℃ × 10min | 71 59 42 |

Elution ratio (%): Calculated after extracting film with hot water at 70℃ for 1 hr

Crosslinker: WS-570 (12.5% solids), manufactured by Seiko PMC

Amount of crosslinker: Active ingredient / PVOH

Biodegradability

| Product | Biodegradability(%) |

| GOHSENOL™ GH-17 | 67 |

| GOHSENX™ T Series | 45 |

Biodegradability test:

Conformed to the “Determination of the ultimate aerobic biodegradability of plastic materials in aqueous culture medium—Method by measuring oxygen consumption using a closed respirometer.” (JIS K6950, ISO 14851:1999)

Test conditions:

Sample concentration: 100 mg/L, microorganism concentration: 90 mg/L, standard test medium: 300 mL,

test temperature: 25±1°C, test duration: 28 days,

active sludge: sludge returned from the Okayama Plant, Mitsubishi Chemical Corporation

Application examples

Paper treatment agents

The product improves the surface strength, printability, and Z-axis strength of paper and prevents vessel pick.

A partially saponified type is effective for improving barrier properties, and is therefore used as an undercoating agent for silicon release paper.

Plywood adhesives

Improves initial bonding strength

Cement mortar agents

Excellent stability under alkaline conditions

Paper coating properties of GOHSENX™ T

| Product | IGT Pick Strength (㎝/sec) | Z-axis Strength (㎏/㎝) | Permeability (sec) | Oil Absorptiveness (sec) |

| GOHSENX™ T-330H | 95 | 2.5 | 10 | 12 |

| GOHSENX™ T-350 | 85 | 2.2 | 35 | 80 |

| GOHSENX™ N-300 | 65 | 1.7 | 8 | 10 |

| Oxidized starch | 50 | 1.3 | 8 | 8 |

Base stock: L-BKP 100%, basis weight 66 g/m2; Size press: 90 m/min, line pressure 11 kg/cm

Drying: 150°C × 3 min; Coating weight: 1 g/m2

Dissolution

Dissolving GOHSENX™ T

Gradually add it to water at room temperature with stirring, and once evenly dispersed, raise the temperature and continue stirring at 80–90℃ for 30–60 minutes until complete dissolution.

GOHSENX™ T effluent water load

| Polymer | COD(㎎/㎏) × 10⁴ | BOD₅(㎎/㎏) × 10² |

| GOHSENX™ T Series | 99 | 83 |

| GOHSENOL™ | 60~100 | 50~100 |

| Corn Starch | 36 | 7,400 |

Measurement conditions:

Chemical oxygen demand (COD) was measured by the potassium permanganate method (JIS K 0102).

BOD₅ is the 5-day biochemical oxygen demand (BOD) value.

Sample concentration: 0.1% aqueous solution as pure material concentration

Measurement: Registration No. of measurement certification enterprise: Osaka No. 10013, KK Osaka Environmental Technology Center

-scaled.jpg)