Reactive PVOH Z Series

Reactive PVOH Z Series: Information

GOHSENX™ Z Series

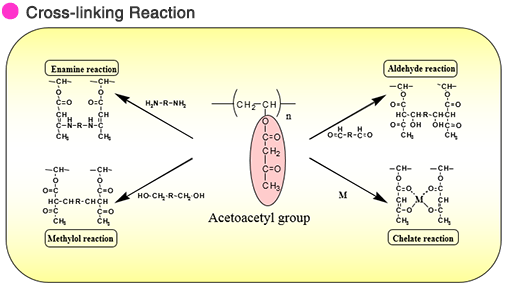

The product is a specially modified PVOH that has a highly reactive acetoacetyl group in the molecular structure.

With the excellent reactivity of its acetoacetyl group, the GOHSENX™ Z series has been widely used both in global and domestic markets as an industrial material and treatment agent for coatings, emulsifiers, adhesives, and binders.

Structural formula

Properties

・Crosslinked by various methods

– Adding a crosslinker

– Self-crosslinking by thermal treatment

-UV crosslinking (in a hydrated or aqueous solution state)

・Functions as a protective colloid and a surfactant

・Adheres especially well to polarized surfaces

・Enables chelate formation

・Easy to break the crosslinking by using alkali

Grades and technical specifications

| Product Grade | Saponification Value(mol %) | Viscosity (mPs・s) | |

| Reactive PVOH Viscosity | GOHSENX™Z | ||

| Z-100 | Min.98.5 | 4.5~6.0 | |

| Z-200 | Min.99.0 | 11.5~14.0 | |

| Z-205 | Min.99.0 | 11.5~14.0 | |

| Z-210 | 95.0~97.0 | 11.5~15.0 | |

| Z-220 | 90.5~92.5 | 11.5~15.0 | |

| Z-300 | 98.0~99.0 | 24.0~30.0 | |

| Z-320 | 92.0~94.0 | 19.0~24.0 | |

| Z-410 | 97.5~98.5 | 43.5~58.5 |

*1: 4% aqueous solution at 20°C

*2: 4% aqueous solution at 30°C

Applications of GOHSENX™ Z (examples)

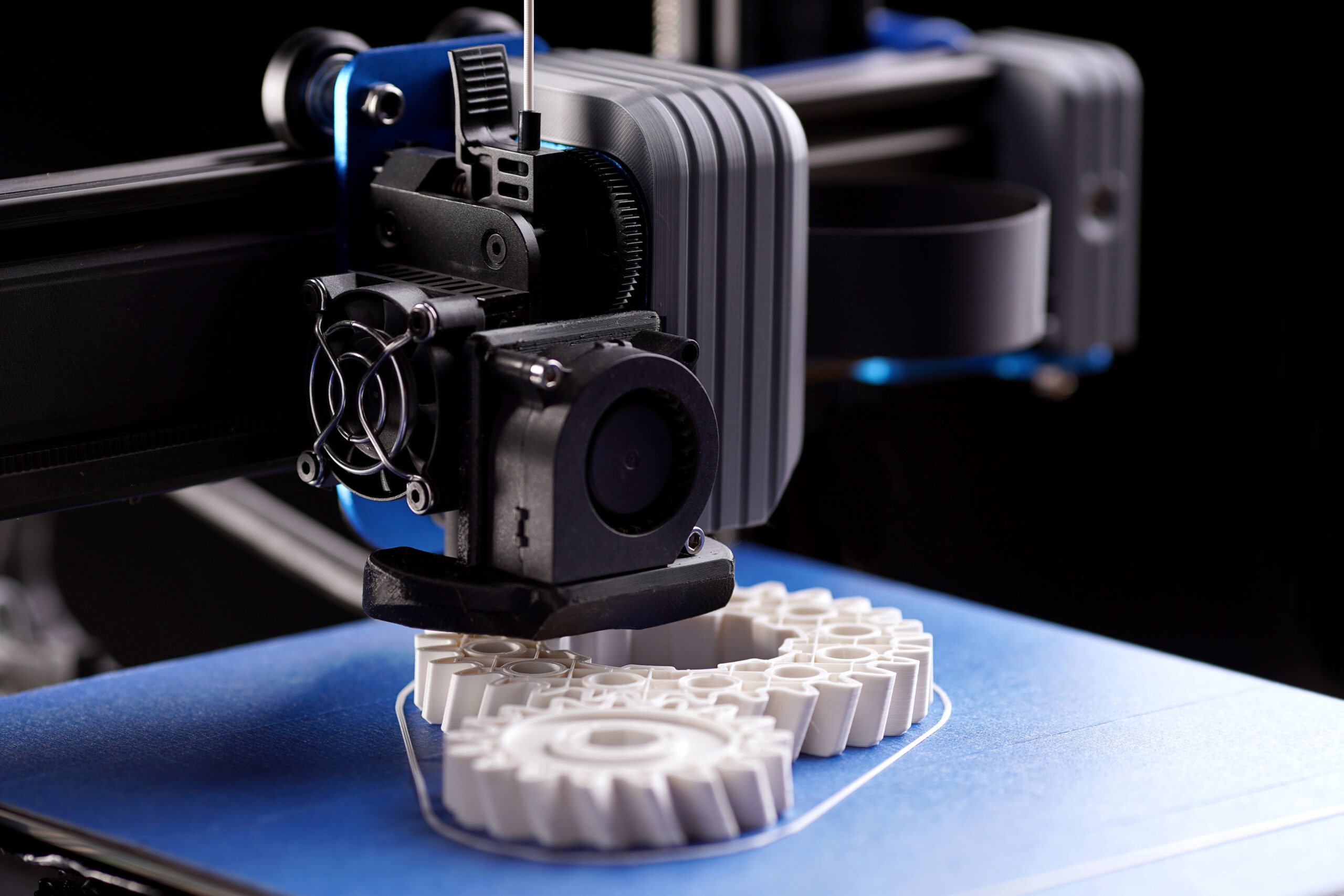

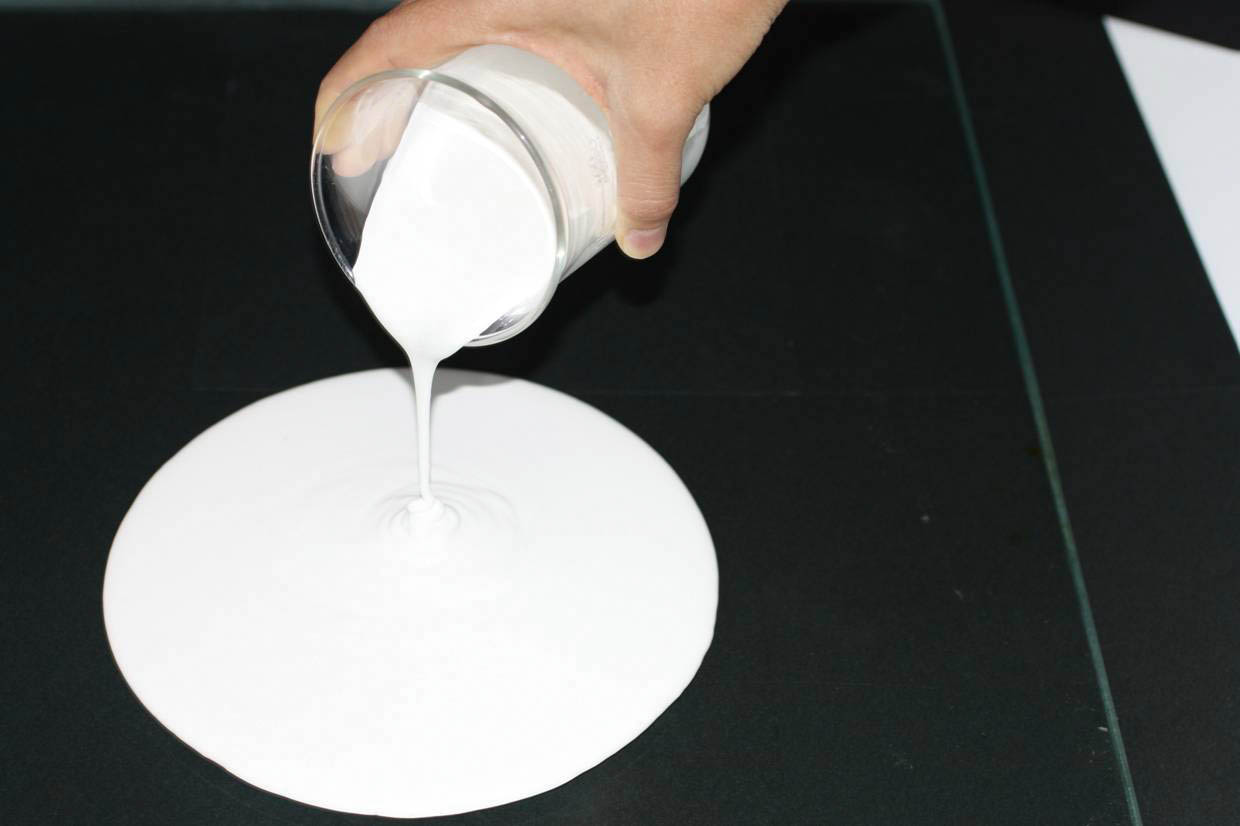

Application to emulsifiers

When used as an emulsifier in polyvinyl acetate emulsions, emulsions with high water resistance and adhesive strength that cannot be obtained with conventional PVOH can be realized.

Application to coating agents

Demand for coated and uncoated papers that require water resistance is increasing, and it is used as a coating agent for thermal paper, inkjet paper, etc.

Application to adhesives and binders

With its excellent bonding to various base materials and added water resistance, GOHSENX™ Z can also be used as an adhesive or binder.

Recommended crosslinker (Safelink™ SPM-01)

Safelink™ SPM-01 is a new crosslinker for GOHSENX™ Z developed with our proprietary technology. Both a powder type and 10% aqueous solution type are available.

Properties

・Excellent crosslinkability for GOHSENX™ Z

・High safety and less toxicity compared to other crosslinkers

・Easy handling with a longer pot life after mixing

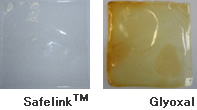

・Crosslinked films have excellent color stability against staining (yellowing) caused by heat and aging.

Crosslinking performance of Safelink™ SPM-01

| Cross-linking Agent | Amount *1 | pH | Elution rate(%) *2 | Pot life *3 | YI *⁴ |

| Safelink™ SPM-01 | 5 | 5.0 | 3 | More than 7days | 4 |

| GIyoxal | 1 | 4.4 | 6 | 7days | 12 |

*1. Active ingredient (part) / Z-200

*2. Elution ratio: dry film, heat treated at 70°C for 5 minutes, and subsequently extracted with hot water at 80℃ for 1 hour

*3. Time to reach twice the initial viscosity of a 7% aqueous solution at 23°C

*4. YI value after leaving a 100 μm thickness film at 40°C, 90%RH for 7 days (NIPPON DENSHOKU, ∑90)

Other crosslinkers

| Crsslinking agent | Product name | Chemical name | Product company | Add- intion*1 | pH | Elution rate(%) *2 | Pot Life *3(hr) |

| Amine | MXDA | Methaxylenediamin | MITSUBISHI GAS CHEMICAL COMPANY, INC. | 3 | 10.5 | 20 | 0.1 |

| 1,3-BAC | 1,3-bis (aminomethyl) cyclohexane | 3 | 10.5 | 20 | 0.1 | ||

| Hydrazide | ADH | Adipoyldihydrazide | Otsuka Chemical Co., Ltd. | 3 | 5.4 | 100 1) | 0.1 |

| APA-280 | 3 | 5.4 | 15 | 0.1 | |||

| Aldehyde | SEQUAREZ 755 | Polyol Carbonyl Adduct | OMNOVA Solutions | 3 | 4.3 | 10 | 9 |

| Metal Salt | ZIRCOZOL ZC-2 | ZrO(OH)ClnH2O | DAIICHI KIGENSO KAGAKU KOGYO CO., LTD. | 5 | 1.9 | 3 | >168 |

| ZIRCOZOL AC-7 | (NH₄)₂ZrO (CO₃)₂ | 5 | 4.8 | 20 2) | >168 |

*1: Active ingredient (part) / Z-200

*2:Elution ratio: dry film, heat treated at 70°C for 5 minutes, and subsequently extracted with hot water at 80℃ for 1 hour

*3:Time to reach twice the initial viscosity of a 10% aqueous solution at 40°C

1):Forming an insoluble film in cold water

2):Elution test result at 90°C

Application of GOHSENX™ Z as an emulsifier (examples)

| Emulsion NO. | 1 | 2 | 3 | 4 | |

| Polymerization Recipe | Z-210(parts) | 4 | – | – | – |

| Z-220(parts) | – | 3 | – | – | |

| N-300(parts) | – | – | 5 | – | |

| GM-14(parts) | – | – | – | 3 | |

| Vinyl acetate(parts) | 36 | 37 | 45 | 47 | |

| Water (parts) | 60 | 60 | 50 | 50 | |

| Polymerization Iinitiator | APS | APS | HPO/TA | APS | |

| Properties | Evaporation Residue(%) | 40 | 40 | 50 | 50 |

| Viscosity(mPa・s, 25°C) | 15,600 | 27,300 | 13,000 | 53,000 | |

| pH | 4.3 | 4.2 | 4.5 | 4 | |

| Apparent Graft Ratio(%) | 76 | 76 | – | 42 | |

| Freeze-thaw Stability (number of cycles) | 5< | 5< | 0 | 5< | |

| Water-proof Adhesion Test | 13hr | 95hr | × | × |

Notes

(1)APS: Ammonium persulfate

(2)Apparent graft ratio: An emulsion film was air-dried at 20°C, treated with acetone at 40°C for 8 hrs and with hot water at 80°C for 8 hrs, and the extraction-residue was calculated.

(3)In the water proof adhesion test, 100g/m2 of emulsion was applied to both surfaces of the birch material. The specimens were then glued together and pressed for 24 hrs at 200 gf/cm². After depressurizing, the resultant sample was left to stand for 24 hrs. This sample was used as a test piece. The test piece was immersed in boiling water and the time until the adhesive surface peeled off was measured.

Properties of Polyvinyl Acetate Emulsion using GOHSENX™ Z as an Emulsifier

| Mixing Ratio | Emulsion Properties | G.f(%) | |||

| Viscosity(mPa・s) | S.V.I | Solids (%) | |||

| Z-200:4 parts | Initiator(APS) : 0.08 parts | 12,000 | 0.5 | 40 | 73 |

| VAC:36 parts | Buffer(NaOAc) : 0.02 parts | ||||

| Pure water:60 parts | |||||

| Z-100:5 parts | Initiator(APS) : 0.08 parts | 2,300 | 0.3 | 50 | 69 |

| VAC:45 parts | Buffer (NaOAc) :0.02 parts | ||||

| Pure water:50 parts | |||||

Viscosity: Brookfield viscometer, 10 rpm, 25°C

S.V.I: Obtained by log (viscosity at 2.5 rpm / viscosity at 20 rpm) / 0.903

Solids: Obtained by drying samples for 3 hrs at 105°C

Apparent graft ratio: An emulsion film was air-dried at 20°C, treated with acetone at 40°C for 8 hrs and with hot water at 80°C for 8 hrs, and the extraction-residue was calculated after repeating this process twice.

* Apparent graft ratio of emulsion using GM-14 (55% solids): 40–50%

UV crosslinking

Crosslinking by UV exposure occurs when GOHSENX™ Z is in a hydrated state.

Dissolution and storage

- Dissolving GOHSENX™ Z

- Put GOHSENX™ Z into water at room temperature while stirring. Heat the water immediately with constant and continuous stirring, keeping the temperature at 90°C to 95°C for 30 to 60 minutes until complete dissolution.

- Storage of GOHSENX™ Z

- The properties of aqueous solutions may change (e.g. viscosity may increase) if stored for a long period of time. Color changes or viscosity increases may also be induced by iron rust or metallic ions entering the solution.

- Notes

- When mixing GOHSENX™ Z with defoaming agents, anticorrosives, antiseptics, or other chemicals, follow the handling instructions for these chemicals.

- Avoid storage in a hot, humid area, as this may cause the product to become blocked or deteriorate.

- Although it is stable during normal storage and handling, it has highly reactive functional groups, so contacting or mixing with other chemicals may cause insolubilization or gelation.

GOHSENX™ Z Effluent Water Load

| Polymer | COC(㎎/㎏) × 10⁴ | BOD₅(㎎/㎏) × 10² |

| GOHSENX™Z | 99 | 70 |

| GOHSENOL™ | 60~100 | 50~100 |

| Corn Starch | 36 | 7,400 |

Measuring conditions: Sample concentration is a 0.1% aqueous solution.

COD was measured by the potassium permanganate method (JIS K 0102), and BOD₅ is the 5-day BOD value.

Measurement: Registration No. of measurement certification enterprise: Osaka No. 10013, KK Osaka Environmental Technology Center

-scaled.jpg)