Gas barrier package materials (coating)

Barrier Films

Recommended grades when using Nichigo G-Polymer™ for barrier films

By coating a base material with Nichigo G-Polymer™ aqueous solution, high gas barrier performance can be added to a barrier film.

Recommended grades for coating a base material with Nichigo G-Polymer™ aqueous solution on a barrier film include the standard grade and low viscosity type.

The respective grades, viscosity, estimated DP, degree of saponification, and melting point are listed below.

| Type | Grade | Viscosity 1) | Degree of polymerization | Saponification value (mol%) | Melting point 2) (℃) |

| Standard | BVE8049Q* | 4.5 | 450 | ≧99.0 | 190 |

| Low viscosity | AZF8035Q* | 3.0 | 300 | ≧98.0 | 172 |

1): Conforms to JIS K 6726-1994 (4% aqueous solution at 20°C, Höppler viscometer)

2) Measured with DSC

* Recommended grade for food package applications

The numbers above are sample values, and are not guaranteed.

Recommended conditions for coating a base material with Nichigo G-Polymer™ aqueous solution

Recommended solvents, solution concentration, and drying temperature for coating are as follows.

– Solvent: water or water-alcohol (e.g. water-ethanol with ethanol at 50 wt% or less)

– Solution concentration: 5–15% (depending on the coating equipment, desired coat thickness, and line speed)

– Drying temperature: 70–120°C

In order to assure adhesion, we recommend the use of a base material film that has undergone corona treatment.

The use of an anchor coating agent is also effective to enhance wettability and adhesion.

Oxygen permeability of Nichigo G-Polymer™ and EVOH

The figure below indicates that Nichigo G-Polymer™ has higher barrier performance than EVOH.

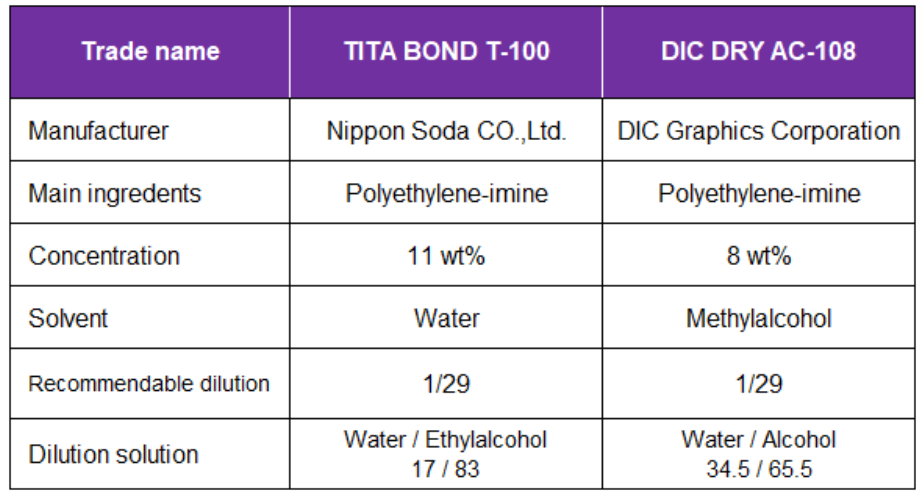

Recommended anchor coating agents

Anchor coating agents recommended by Mitsubishi Chemical

[Anchor coating agents (hydrophilic)]

We recommend the hydrophilic anchor coating agents shown in the figure below.

(Also see materials provided by manufacturers of AC agents.)

By adding a wetting agent, the product can also be applied to hydrophobic anchor coat layers.

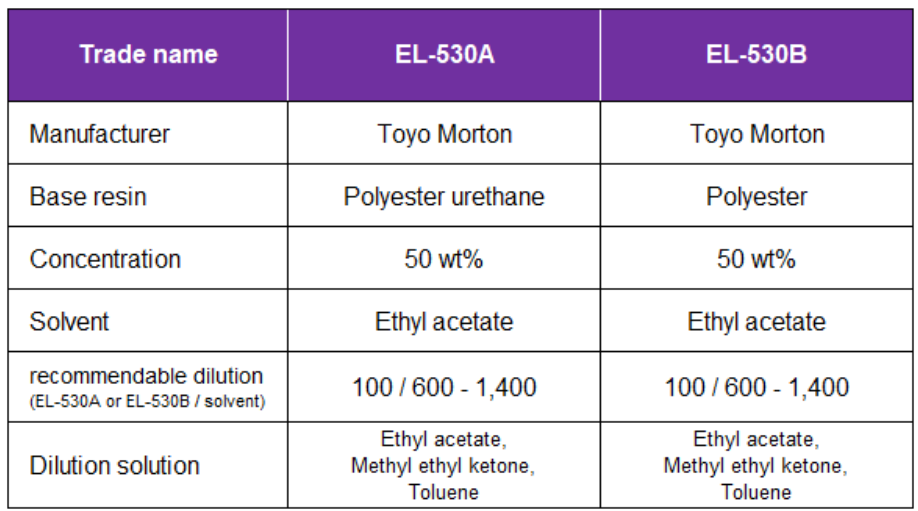

We recommend the hydrophobic anchor coating agents shown in the figure below.

(Also see materials provided by manufacturers of AC agents.)

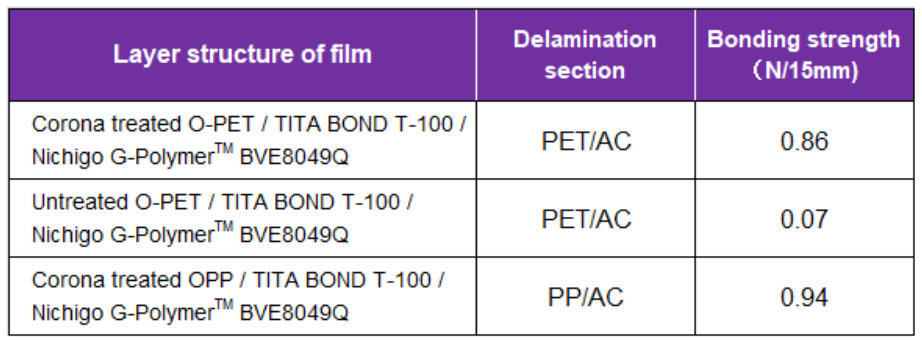

[Bonding strength]

The bonding strengths of barrier films are as listed below.

Recommended wetting agents

The use of a wetting agent is recommended when coating Nichigo G-Polymer™ aqueous solution over an anchor coating agent layer on a base material.

The wetting agent recommended by Mitsubishi Chemical is Olfine EXP-4123, Nissin Chemical Industry. http://www.nissin-chem.co.jp/products/olfine.html

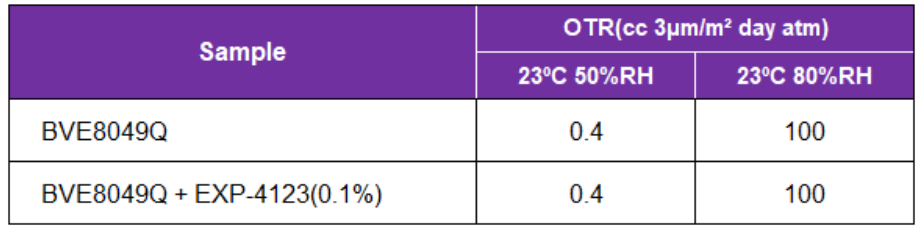

By adding a wetting agent at 0.1 wt%, Nichigo G-Polymer™ aqueous solution can be applied not only to hydrophilic anchor coating layers but also to hydrophobic anchor coating layers.

Additionally, there is almost no decrease in gas barrier performance when using a wetting agent.

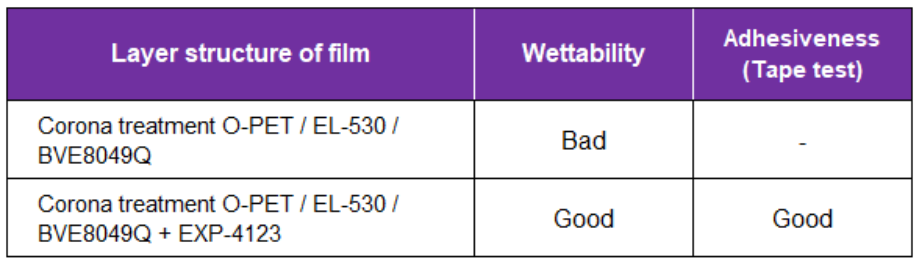

The film structure of a recommended wetting agent is as listed below.

Recommended wetting agents (film structures)

Examples of recommended wetting agents are as listed below.

Recommended wetting agents (examples)

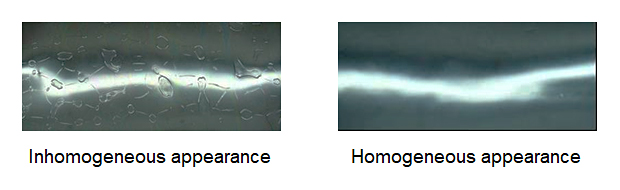

As indicated below, wettability on a base material can be improved by using a wetting agent.