Inorganic Dispersion Stability

Inorganic Dispersion Stability

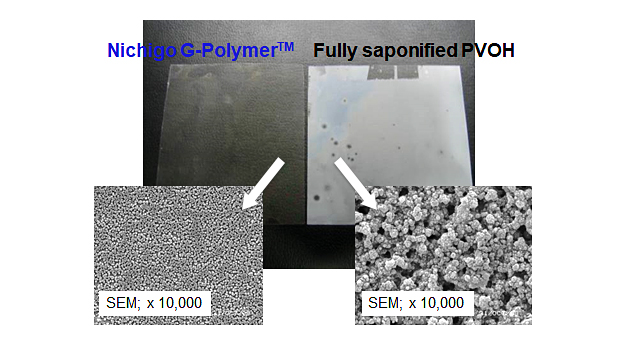

Nichigo G-Polymer™ shows good dispersibility for hydrophilic inorganic pigments such as silica and alumina when added in small amounts.

When added in small amounts, it also exhibits favorable dispersibility with colloidal silica, forming films with outstanding transparency and luster.

[Test conditions]

Disperse the mixed anionic colloidal silica / resin aqueous solution with a homogenizer (5,000 rpm for 5 min).

After coating the PET film with a bar coater, film luster was measured after drying at 105℃ for 5 minutes.

The actual PET film coated with the mixture was observed using a microscope.

[Film producing conditions]

Anionic colloidal silica/resin = 90 / 10 (wt%)

1. Prepare a mixed aqueous solution of silica and resin.

2. Disperse it evenly using a homogenizer (5,000 rpm for 5 min).

3. After coating an O-PET film with the aqueous solution using a bar coater, dry it at 105°C for 5 min.

By using Nichigo G-Polymer™ as a dispersant, colloidal silica can be stably dispersed in a wider pH range.

Mixture: silica/resin = 80/20

Silica A: SNOWTEX 20 (Alkaline type), Nissan Chemical Industries, Ltd.

Average particle size: 10–20 nm, pH10, Isoelectric point: pH2

Silica B: SNOWTEX C (Al treated surface type), Nissan Chemical Industries, Ltd.

Average particle size: 10–20 nm, pH8.5–9.5, Isoelectric point: pH2–3

Silica C: SNOWTEX OL (Acidic type), Nissan Chemical Industries, Ltd.

Average particle size: 40–50 nm, pH2–4, Isoelectric point: pH2

-scaled.jpg)