Gas Barrier Performance

What is Gas Barrier Performance?

Gas barrier performance is the ability of a film or packaging material to resist the transmission of gases such as oxygen and water vapor.

This helps maintain the quality of food and pharmaceuticals for a long period of time.

For example, blocking oxygen prevents food from oxidizing and preserves its freshness and flavor. In addition, blocking water vapor can also prevent moisture-sensitive products from deteriorating.

To enhance gas barrier performance, multilayer films using aluminum foil or special resins are commonly used.

Gas barrier performance of Nichigo G-Polymer™

Despite its low crystallinity, Nichigo G-Polymer™ exhibits higher gas barrier performance than conventional PVOH, owing to its high hydrogen bonding strength.

Oxygen gas barrier performance

Nichigo G-Polymer™ has a 30- to 600-fold higher oxygen gas barrier performance under dry conditions compared to ethylene vinyl alcohol (EVOH), which is commonly used as an oxygen gas barrier material.

Sample: solution coating film (single layer film is used for Nylon 6 and polypropylene)

Measurement conditions: 20°C, dry

Please use the following simulator to check the oxygen transmission rate according to material, structure and thickness.

Oxygen transmission rate simulation soft (GTR Simulator Lite)

Hydrogen gas barrier performance

Nichigo G-Polymer™ demonstrates the highest hydrogen gas barrier performance among thermoplastic resins.

Sample: single layer film

Measurement conditions: dry

Nichigo G-Polymer™, EVOH: 41°C

Nylon resin: room temperature

Carbon dioxide gas barrier performance

Nichigo G-Polymer™ demonstrates extremely high carbon dioxide gas barrier performance.

Sample: biaxial stretched film

Measurement conditions: 20°C, dry

Humidity dependence

The gas barrier performance of Nichigo G-Polymer™ is humidity-dependent.

Samples: PP/tie/Nichigo G-Polymer™ BVE8049P (or EVOH)/tie/PP multilayer film

Measurement conditions: 23°C

Please use the following simulator to check the oxygen transmission rate according to material, structure and thickness.

Oxygen transmission rate simulation soft (GTR Simulator Lite)

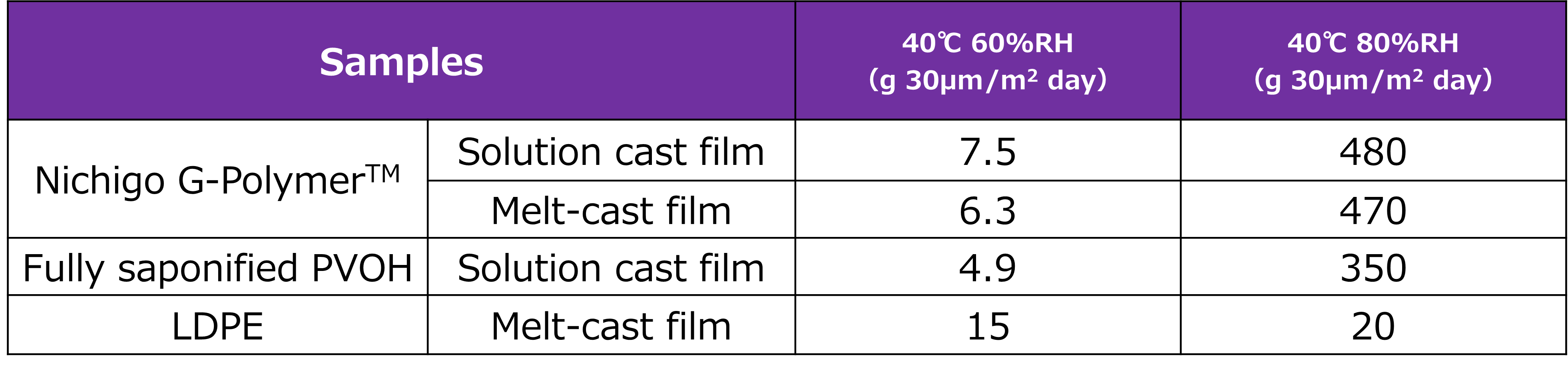

Vapor permeability

Nichigo G-Polymer™: BVE8049Q (extrusion cast film: BVE8049P)

Measurement method: cup method

Sample: 30 μ single layer film

-scaled.jpg)