Extrusion Performance

Extrusion Performance

Nichigo G-Polymer™ is a resin capable of extrusion casting.

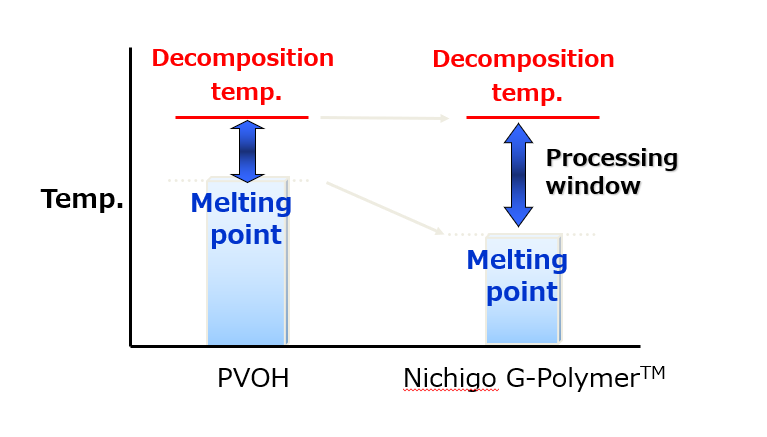

Compared to PVOH, Nichigo G-Polymer™ has a lower melting point and a wider casting temperature range, giving it outstanding extrusion performance.

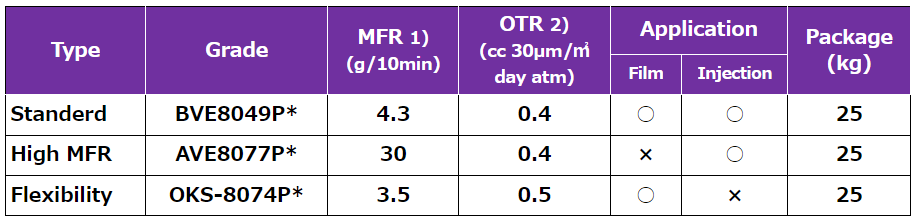

Recommended grades for casting

1): 2,160 gf, 210°C

2): 23°C, 65%RH

* Recommended grade for food package applications

The numbers above are sample values, and are not guaranteed.

Important points for extrusion casting

* Keep the resin at a temperature lower than 230°C to avoid fluidity changes and gel formation due to thermal decomposition.

* Do not leave the resin in an extruder or extrusion die for a long period of time. It may cause fluidity changes or gel formation.

* Use the resin quickly after opening the package, as it is hygroscopic. If long-term storage is necessary, store it in a heat sealed moisture-proof bag.

* Redrying is not recommended, as it may cause yellowing or fish eyes.

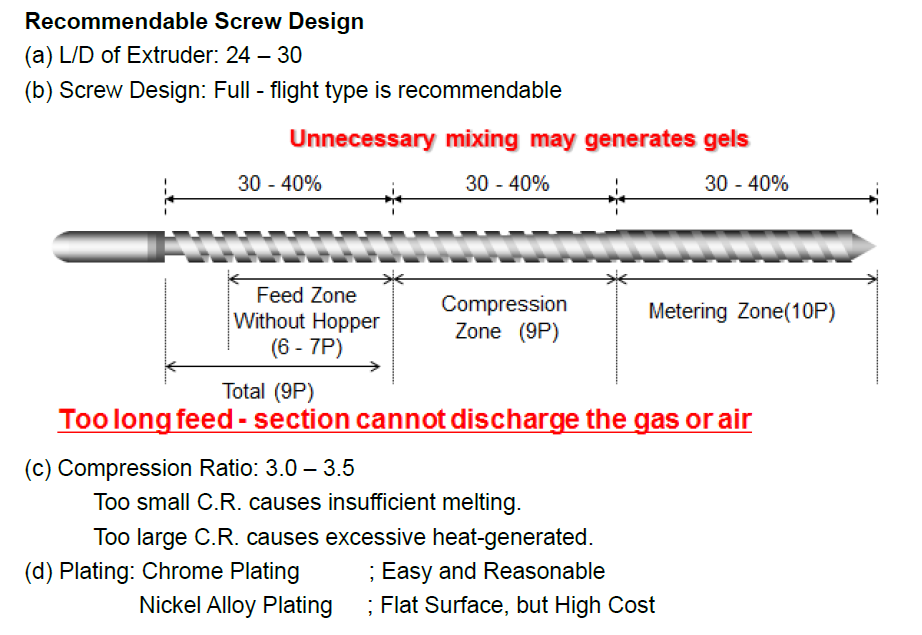

* Heating due to shearing of the resin is likely to occur. Choose a mild screw pattern and do not use a finer screen mesh.

* Thermal decomposition can be suppressed by filling up the equipment with nitrogen gas.

* Nichigo G-Polymer™ is a hydrophilic resin, so it is nearly incompatible with hydrophobic general-purpose molding resins. A compatibilizing agent is needed for high-concentration blending.

* To the extent possible, avoid leaving Nichigo G-Polymer™ in the processing equipment. Doing so could result in foaming and gelification. When stopping processing, purge it with LDPE or LLDPE. The maximum amount of time it can be left in equipment is approximately 20 minutes.

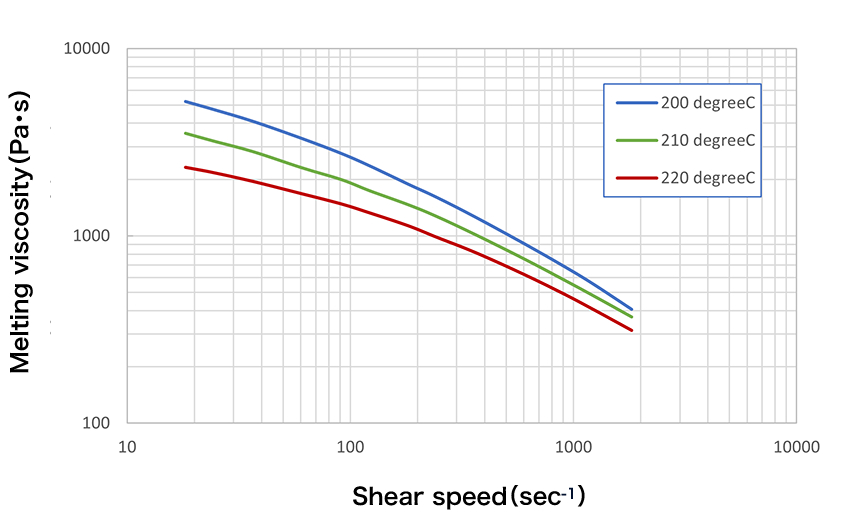

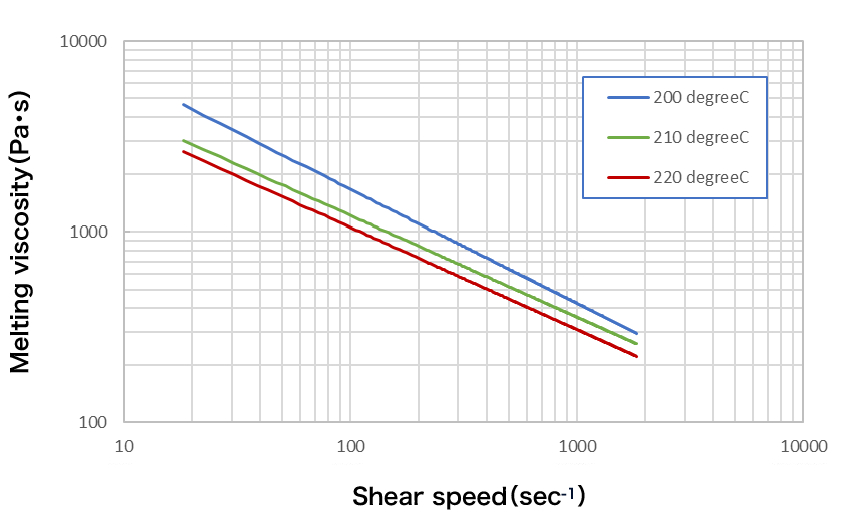

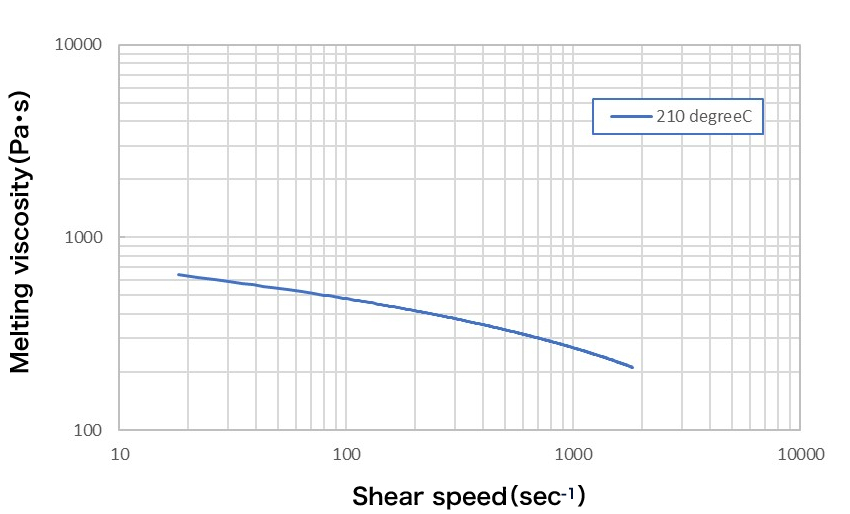

Extrusion viscosity (depending on shear rate)

BVE8049P

OKS-8074P

AVE8077P

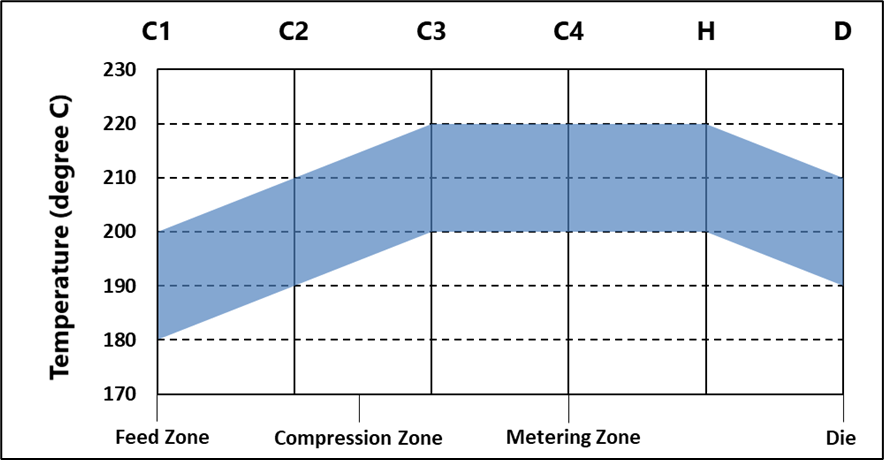

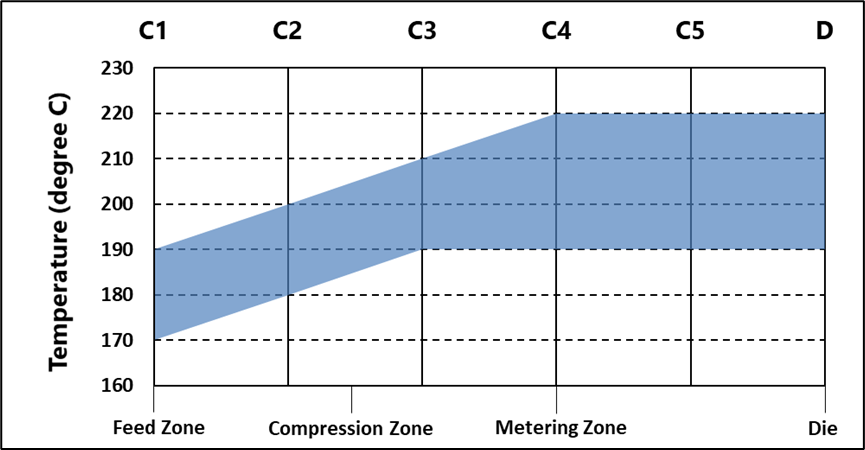

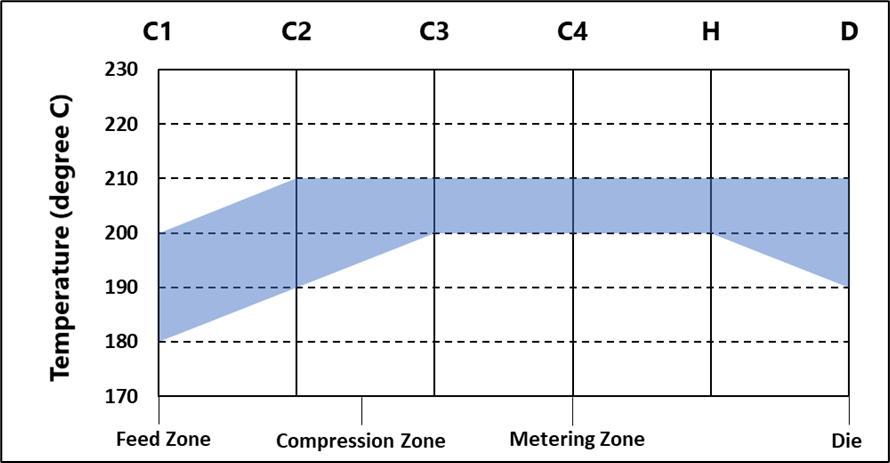

Extrusion casting temperature range and temperature slope

We recommend casting at temperatures of 220°C or less in order to assure stable processing.

[Precautions]

– Cooling the bottom of the hopper is recommended.

– An excessively long measuring section causes gel formation.

– If the feeding screw groove is narrow, pellet feed problems may occur.

– If pellets are fed while the feeder screw is hot, pellets may get stuck and cause clogging.

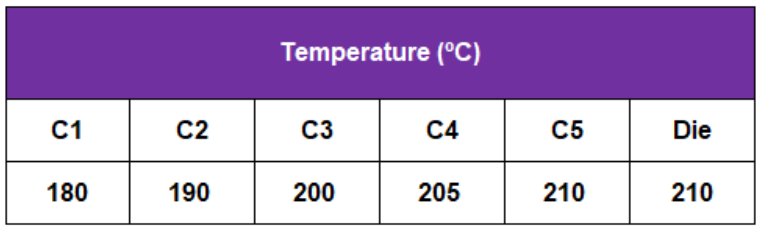

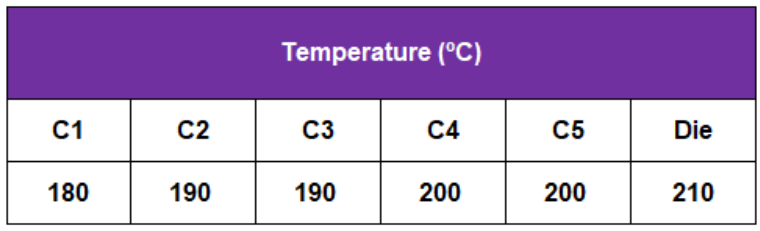

BVE8049P

AVE8077P

OKS-8074P

Inflation treatment condition examples

[Equipment used]

Inflation extruder (Placo Co., Ltd., L-40A, 40 mmφ, L/D = 28)

Resins used: Nichigo G-Polymer™ BVE8049P and OKS-8074P

[Setup conditions]

– Screw pattern: full flight

– Ring caliber: 46 mm

Extrusion casting treatment condition examples

[Equipment used]

Single axis extruder (L/D = 28, 40 mmφ)

Resins used: Nichigo G-Polymer™ BVE8049P and OKS-8074P

[Setup conditions]

– Screw pattern: full flight

– Screen mesh: 90 mesh × 2

– Hanger coat die

Temperature regulation cooling roll: 50–80°C